Ship Welding Robot

I worked at CERLAB CMU on the ship welding robot team from January 2016 to May 2018. Below are our goal and the reason we are passionate about this project:

We want to automate the ship building process

Shipbuilders need to weld different compartments together

Used to be done manually in confined space inside compartments

Help Tsuneishi to develop ship welding robot to automate the process

Challenge

•Need to get through longis, manholes, curved surface as shown above

•Able to perform accurate, consistent welding under tough conditions, which is needed between compartments, longis and the ground

•Perform the welding automatically, meaning the robot would need to locate itself and navigate automatically

CAD for working environment of the welding robot

Problem Definition: Red part is mainly what I am responsible for

Concept Generation

When I joined the group, we were still in the stage of concept generation and just finished the first prototyping stage.

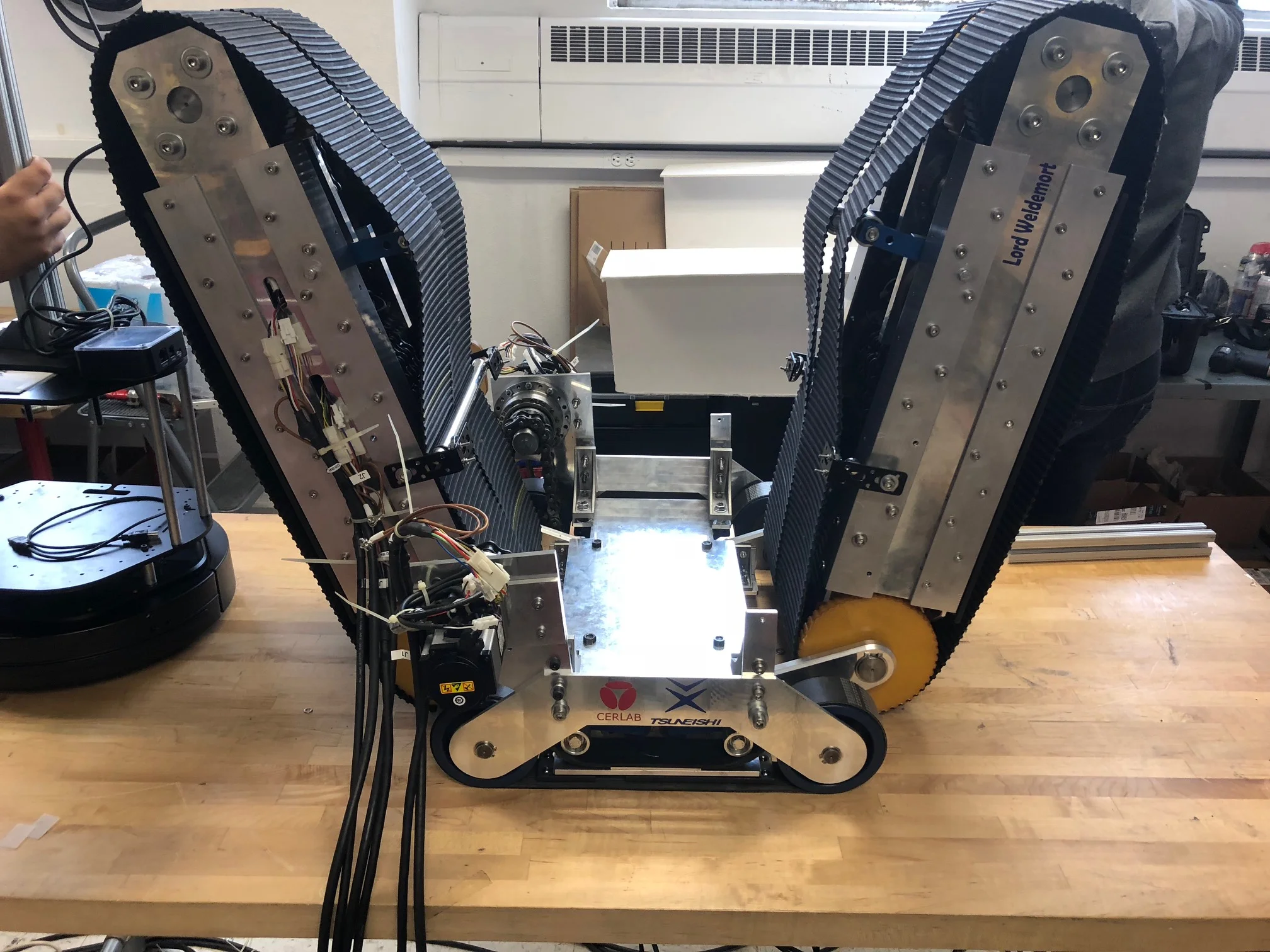

We decided on the basic main body + two arms assembly with the belt drive being the main transportation system

As shown on the left, the robot would have:

One Main body which carries a Denso robotic arm and Lidar, there would also be two belts running through both sides

Two arms pivoting to push robots up and through the longis and manhole, each arm has timing belts rotating around to assist with the mobility

Map generated from Lidar

PerCeption + Welding

Use a denso robot arm to carry the welding tip

Offer great accuracy and large range of motion

Use a velodyne lidar for perception

Lidar generates 3D surrounding map

Localization algorithm to locate the robot and navigate

CAD for the robot in early stage

How it navigates

As shown by the images below, the robot fully utilizes its two arms to navigate inside the ship

My responsibility

I was responsible for the mobility system development

Belt Choice and Design

Suggested we went with the belt and drum combination

Studied which type of belt + drum combination works the best for arm drive and body drive

Decided to use flat belt with groves inside and double sided timing belt for the main body and arm drive

Fixture and structure design/analysis

Designed side panel and side plate to mount the motors and harmonic drive in Solidworks

Helped arranging the placement of motor, chain drive and mounting plates

Perform FEA on components to ensure strength with Solidworks and Ansys

Prototyping, Manufacturing and testing

Programmed CAM files for CNC of multiple parts

Selected catalog components for prototyping

Designed testing equipment/setup to test the robot